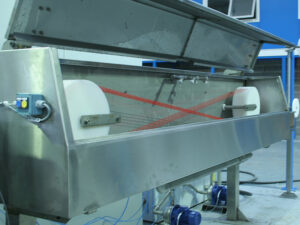

Extrusion Line Water Troughs

Water troughs are supplied as part of an extrusion line to cool the insulation of sheathing material enough to allow winding onto a drum, without damaging the product.

Various designs are available to suit different cables and line speeds. The typical process is as follows:

- An initial straight length of water trough is used to fix the product dimension.

- A multipass section then sends the product around several pulleys using pulleys inside an enclosure where sprayed cooling water is applied.

- This is followed by an air wipe to remove excess water.

The multipass section cools the product so that its dimension is stable enough for winding.

Chiller units, storage tanks and pump systems are supplied.

The first section of trough is telescopic to allow the positioning in relation to the diehead to be adjusted. This section may also be supplied with hot water to suit the process.

For special applications vertical cooling troughs are supplied.